Personalised Items & Gifts …

Our company deals with the professional personalisation of promotional gifts (pens and clothing, advertising gadgets, personalised items for events, paper bags, bags, mugs and other gifts for advertising). Our offer also includes lanyards, external batteries, memory sticks and more than 1000 other customized items.

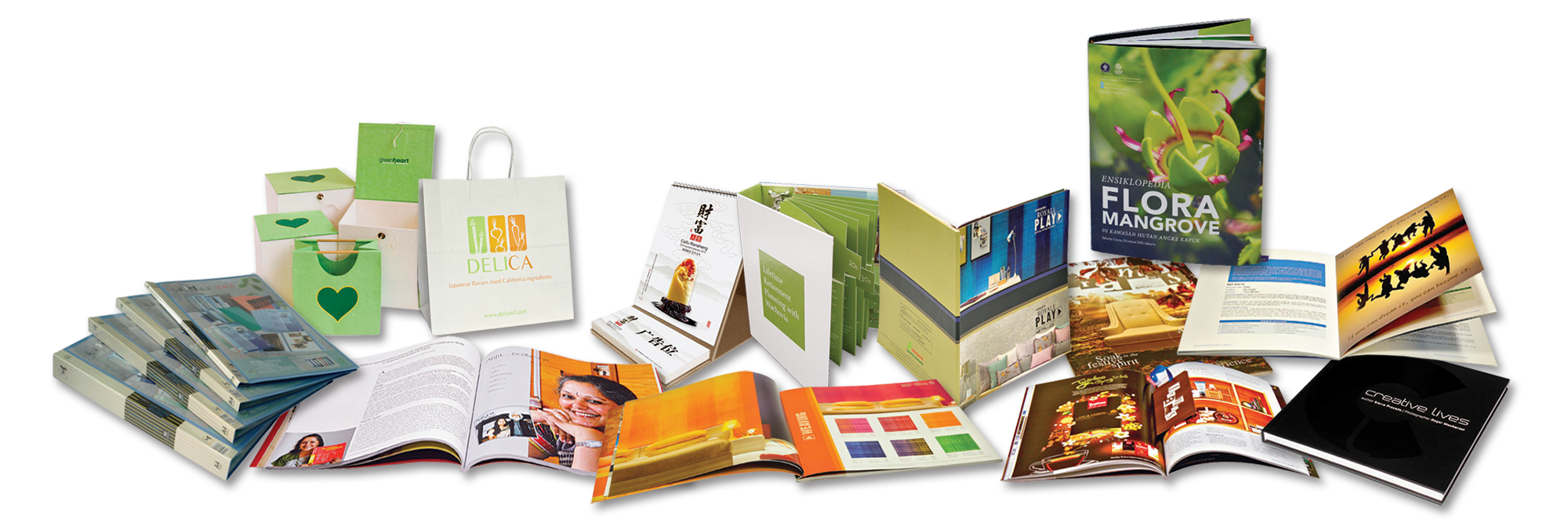

We offer our customers complete services including consulting, design, import and export. Our vast experience will make your orders run with the utmost precision and achievements in an emergency. We also handle digitally printed orders, offset or flexographic items. You can choose between notebooks, notepads, office calendars, wallpapers, advertising flyers, magazines, presentation cards, catalogs, business cards or personalized cards, invitations, entrance tickets, tickets and more.

Due to the diversity and specificity of each institution or company, all requests and orders accepted by us are individually treated. We strive to achieve all our products at a high level of quality and safety, while maintaining the most competitive and low possible prices.

The professional placement of the logo requires a good knowledge of the material. We offer our customers a lot of creative ideas from the technical side. We have a wide range of customization and print advertising techniques such as laser engraving, tampo printing and serigraphy, thermal transfer and folio, embroidery, sublimation, decal composition, offset, flexo and digital printing. We are able to offer our customers complete services for selected items in our catalogs or made by you starting with orders from several tens to hundreds and thousands of pieces. Thanks to the experience we have gained over the years, we are able to offer you the most effective solutions.

Below you can search in our catalogues, and find a wide range of services and technologies that put all your ideas into practice.

Search in catalogues:

Digital printing . . .

Digital printing is a modern process of professional printing on a variety of surfaces, having a digital image as a source.

This process provides increased flexibility and the materials for printing can be changed very easily before printing in the final version.

Characteristics:

Maximum format: SRA3 = 45 cm x 32 cm

Print size: 44 cm x 31,2 cm

Maximum resolution: 1200 x 1200 dpi

MATERIALS TO BE PRINTING: Paper, paper / PVC sticker (plasticized) – max SRA3

Offset printing . . .

Offset printing, has long been the main method of printing a colour image on paper, but currently we have a number of modern colour printing methods.

However, for larger prints, the offset pattern remains the best option with reference to the price-quality ratio. The offset printing is done by transferring the liquid ink from the printing plate to an intermediate surface and then on the final paper support. We carry out printed works between 60 and 350 gr / sqm; paper and offset cardboard, double and triple chrome, chromo, duplex, colourful cartons, special paper for labels, self-copying, self-adhesive paper, etc.

Documents . . .

Before considering any completed work, a series of finishing steps are needed. After printing almost any document and work needs a short finish. To give a more special look to the final work, we also offer finishing services such as:

- Cutting to finished format

- Matte or glossy wrap, lamination

- Coating (offset, UV selective, total UV);

- Spiral, binder;

- Punching, stamping;

- Bracing to hold sheets between them;

UV Printing . . .

In many processes, ink or toner does not penetrate the substrate just like conventional ink but forms a thin layer on the surface, which may be adherent to the substrate, using a fusion fluid with a heat base or a UV curing (ink) process.

Recommendations:

- Do not print after the Pantone model; they are interpreted by CMYK ink.

- Print features depend on printer performance, but we have the following suggestions:

- When the registration mark ® appears it must be more than 1 mm high;

- The positive text should have a height of more than 1.2 mm;

- Negative text must have a height of more than 1.5 mm;

- Line width in positive should be greater than 0.08 mm;

- The negative line thickness must be greater than 0.17 mm;

- The gradient line thickness must be at least 0.5 pt (0.17 mm).

- The gradient minimum must be C: 8% / M: 8% / Y: 12% / K: 8%.

- Maximum size / sheet: SRA3 – 330 x 488 mm

- Maximum print area: 600 x 420 mm

UV Printing is a modern and advantageous method that has a number of advantages:

- This digital technology has the advantage of printing polychromic directly on the desired objects;

- A wide range of promotional items can be printed: pens, usb, lighters, notebooks, etc;

- You can customize a smaller print, even 1 piece, because there are not many training costs;

- Offers a great print quality and reliability;

- Execution time is short;

- It can be made on different surfaces: plastic, metal, wood, paper, leather and faux leather

Sublimation . . .

Sublimation is a method of applying a special film to a final surface (cups, ceramic glasses) using three basic ingredients: ink, heat and pressure.

Subliming ink is unique in its ability to move from solid to gaseous without passing through liquid form. Conversion is initiated by heat and controlled by pressure and time.

- Sublimation is the process where the color changes from the printed film to the final surface.

- Only works on white surfaces and synthetic materials or other pretreated materials.

- Sublimed images resist scouring and scratching, the image being protected inside the material.

The difference between sublimation and other transfer techniques using dye or pigment inks is that sublimation guarantees 100% resistance to applied images, while other techniques do not.

Recommendations:

Being a digital print image, the restrictions are reduced to the printer’s performance:

- The TM mark or trademark ® will not be visible at a height of 1 mm;

- Positive textures must have a height of more than 1.2 mm;

- Negative text must have a height of more than 1.5 mm;

- Gradient text must have a height of more than 2.4 mm;

- The line width in positive must be greater than 0.08 mm;

- The negative line thickness must be greater than 0.17 mm;

- The gradient line thickness must be greater than 0.5 pt (0.17 mm);

- Gradient Minimum C: 8% / M: 8% / Y: 12% / K: 8%

Pad printing . . .

Pad printing is used to print detailed drawings or images on different objects, irregular objects with a cylindrical or planar surface.

The method is used for printing on pens, office items, plastic lighters.

The diversity of applications makes this technique the most convenient, cheap and versatile.

Some articles require pre-treatment or post-treatment.

Recommendations:

- Improved fingerprint quality requires:

- Details as a trademark TM or trademark ® must have a height of more than 0.8 mm;

- Positive texts must have a height of more than 1 mm;

- Negative text must have a height of more than 1.5 mm;

- The line width in positive should be greater than 0.3 pt (0.1 mm);

- Negative line thickness must be greater than 0.7 pt (0.25 mm);

- The gradient line thickness must be greater than 1.5 pt (0.5 mm).

Laser printing . . .

This technique uses a laser beam to print a logo, text, or other design by engraving directly on the surface of the material. It is generally used for metals and wood.

The result of engraving depends on the type of engraved material. Metal can be engraved in several ways:

- One of them is directly on the surface of the item and it depends on the type of metal

- On painted metals, the paint layer will be removed and the metal color will be revealed (gold or silver)

Recommendations:

The maximum size of engraving is given by the shape and the possible surface of the product to be personalized.

For flat surfaces, the maximum engraving size is 80 x 45 mm.

For this technique the restrictions are:

- TM or trademark ® details will not be visible below the 0.8 mm height;Positive texts must be greater than 1.0 mm high;

- Negative text must have a height greater than 1.5 mm – it is not recommended

- The line width in positive shall be greater than 0.02 mm;

- The negative line thickness must be greater than 0.12 mm;

- Gradients are not possible

Advantages of Laser Engraving:

- Through the engraving we get a permanent image or text with a detailed, fine texture and high quality;

- You can personalize objects with small and fine details as the engraving needle is very thin;

- Engraving resists over time, it is definitive and can not be erased

CNC Cutting . . .

The CNC router is used for cutting and engraving in large format for letter contouring or other volumetric forms.

In order to be able to run a product on the CNC, we need files in vector format.

The materials that can be debited at the CNC router are as follows: plexiglass, comatex, plastic ABS, forex, wood, MDF, plywood, polystyrene, alucubond

Serigraphy . . .

Serigraphy is a printing process that is performed on smooth surfaces and consists of applying an ink layer through a cut pattern covered with a fine sieve.

This technique is used to print images or graphics on different items, such as: t-shirts, jackets, hats, etc., as well as the most diverse materials like paper, plastics, textiles or metals.

The first rule is that the base material must be plan.

The process consists in applying a layer of ink to the material through a mesh. Printing can be done in one

or more manual, automatic or semi-automatic colors.

Dimensions can vary from 0.5×0.5 cm to 40×55 cm.

There are some recommendations:

- The TM mark or trademark ® will not be visible at a height of 2 mm;

- Positive textures must have a height of more than 2.5 mm;

- Negative text must have a height greater than 3 mm;

- Slim gradient textures are not possible / avoided;

- The line width in positive shall be greater than 0.25 mm;

- The negative line thickness must be greater than 0.45 mm;

- The gradient line thickness must be greater than 1.5 pt (0.5 mm).

For textile printing, the restrictions are:

- Positive and negative text must be greater than 5 mm;

- Positive / negative line thickness should be greater than 0.35 mm.

Embroidery . . .

Embroidery technique highlights the logo with elegance, the logo being embroidered on the surface of the item.

Embroidery can be done on simple surfaces (clothing) or on uneven surfaces such as hats, backpacks, bags, etc.

Recommendations:

- Depending on the article and frame size *, there are some maximum embroidery sizes.

- The minimum font size is 5 mm high;

- The thickness of the line must be at least 1 mm thick;

- Gradients are not possible.

Vibrant colours, silky thread and its resistance to chlorine make Polyneon wire ideal for embroidery on uniforms, safety clothing and other commercial use clothing.

Special techniques

- Embroidery is used to create monograms, applies especially to towels, blankets and wool jackets.

- Puff 3D – 3D swelling embroidery uses a special foam under the seams to get a three-dimensional effect

- The foam contains a variety of widths and colours to match the colours of the elements and the threads

- Pocket embroidery works best for rounded capital letters

- The inflatable embroidery logo must have rounded corners so that the wires can completely cover the foam.

Doming . . .

Doming is a printing technique in which several materials are applied, especially stickers, with a transparent layer. A layer of resin (epoxy resin) gives a 3-D lens effect, and the depth and extra brightness in colour.

The coating can be applied in liquid form in several different ways. Once applied, the polyurethane fluid flows on the edge of the label and stops (due to superficial liquid tension), hardening in a clear dome.

The first layer is the label material. The second layer is ink. The label can be multiple colors (CMYK), photo quality graphics, or plain text.

Ink is applied by screen or digital printing technology. After the inks have hardened, the labels are cut by laser or stamping and the residual material between the labels is removed from the press sheet. The liquid polyurethane material is then applied to the labels on the press sheet and allowed to harden.

Recommendations:

For this technique there is no limitation beside the size and shape of the elements.

- The TM mark or trademark ® will not be visible at a height of 1 mm;

- Positive textures must have a height of more than 1.2 mm;

- Negative text must have a height of more than 1.5 mm;

- Gradient texts must have a height of more than 2.4 mm;

- The line width in positive must be greater than 0.08 mm;

- The negative line thickness must be greater than 0.17 mm;

- The gradient line thickness must be greater than 0.5 pt (0.17 mm);

- The gradient minimum must be C: 8% / M: 8% / Y: 12% / K: 8%.

Graphic Design . . .

We create graphic concepts for logo, flyers, posters, brochures and many other advertising products. If you want to place an order and you do not have the new graphics ready, we can ensure the realization of the projects.

These include:

- Create logo / logo;

- Making identity manuals;

- Business card graphics, flyers, brochures, leaflets, posters, magazines;

- Envelopes and letterhead, envelope labels;

- Presentation folders;

- Notebooks, spiral notepads;

- Diplomas, certificates;

- Badges

- Registers, various documents;

- Various other materials;

Graphics are charged separately from the products and service price depending on the complexity of the work done. Before any customization or printing command is released, a simulation will be sent to the client of how the product will look and will be asked to “Confirm” – which is the client’s agreement on the final shape of the layout to be printed.

Any graphic or textual differences that occur between the print asset and the printed work fall under our responsibility, this also involving the additional costs necessary to remedy them. Only after obtaining the print asset can the paper be printed.

Any mistakes in the benchmark are the responsibility of the client, as well as the expenses for their remedy. For orders where the customer has provided the customization materials in the appropriate format (vector, clear images) that no longer require machining, the simulation is included in the final price.